WELDING SHOP SUCTION SOLUTIONS

Welding shop suction solution can sorte into the two groups:

- Local suction – The emissions are suctioned from place where is placed main pollution source.

- Spatial suction – The emissions are suctioned from the whole production space. For this type of welding shop suction solution is installed ventilation system.

Local suction solution is possible to use where the welding works are situated in the same place. This solution uses suction arms, variable covers, industrial suction hoods etc. Suctioned dust does not flow over the welder breathing zone. This suction solutions is most effective solutions from welder health aspect. There is one disadvantage, welders do not want to use this equipment because they very often think is unnecessary

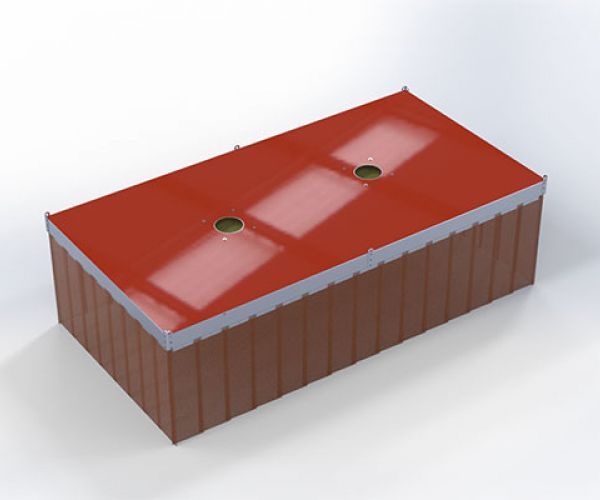

Spatial suction solution is usually alternative solution toward a local suction. Main advantage this suction type is that the all emissions are suctioned from production space without welder service. There is also used ventilation system what can get better work conditions inside a production hall. Solution is adapted according primary production requirements and also is controlled automatically. Spatial suction use to be installed for production where is needed to weld huge components.

Welding rooms have always installed filtrations system with the filtration devices, what enable to air filter return back to the production zone. Residual emissions maximum range is up to 0,5 mg/m3. The whole suction technology has automatic operation according primary production technology.

If you need to know more information about welding shop suction solutions please let us know.