GRINDING ROOM SUCTION SOLUTIONS

Grinding room suction for hand-operated and machine grinding can be solved as:

- Local suction - The emissions are suctioned from place where is placed main pollution source.

- Spatial suction type – Suction is solved by suctioned labyrinths and demarcationed of grinding place.

- Spatial suction type – There is used suction box solution.

Local suction solution is possible to use where are used stationary grinding machines. Grinding machines have emission outlet which is possible to use for connect to the suction technology. This type has huge abrasion of conduit therefore the conduit has to be solved according group III. (Czech technical norm)

Spatial suction 1. type is used in case of the production works take place in the production hall and created emissions are not possible effective suctioned and also there are not possible prevent to the emission flow into hall atmosphere. This suction type is installed according construction hall disposition. There are used the appropriate labyrinths, walls or grate floor.

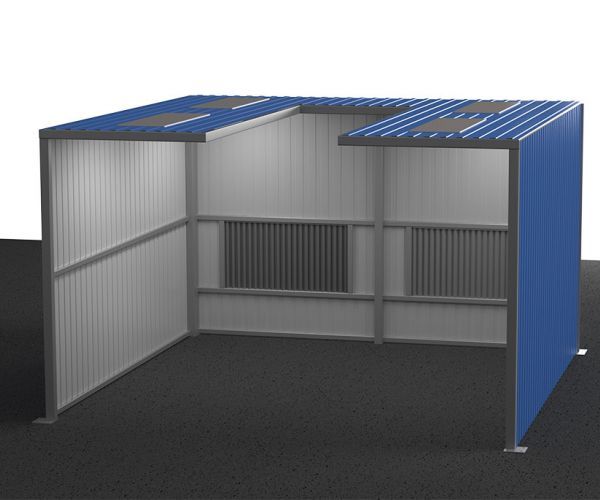

Spatial suction 2. type is used where is necessary to isolate the whole emissions flow. This solutions is solved according customer requirements. We are able to prepare project which include lights, sockets, crane, propulsition etc. There are also used the appropriate labyrinths, walls or grate floor.

Grinding rooms have always installed filtrations system with the filtration devices, what enable filtered air return back to the production zone. Residual emissions maximum range is up to 0,5 mg/m3. The whole suction technology has automatic operation according primary production technology.

If you need to know more information about grinding room suction solutions please let us know.